Binding Styles and Finishing Options

If you’re new to book printing, the range of choices available can be a little overwhelming at first. Here we explain some of the more common options. Of course, we offer much more than we can cover on this site, so please give us a call or drop us an email if you can’t see what you want, or if you wish to discuss your options in more detail.

Paperback Binding Options

Paperbacks are a very cost-effective way to produce your book. They’ve been around since the mid-19th century and were originally used for niche things like railway guides and “penny dreadfuls” – however, from 1935 onwards, Penguin Books, with their eye-catching branding and affordable pricing, really drove them into the mainstream.

Things have moved on since then, of course, with innovations such as picture covers, lamination and embossed or foiled titling.

In recent years, paperbacks have made up roughly 65% of all printed books sold.

Aside from fundamentals like paper type and weight, the main options for paperbacks are perfect binding or sewn perfect binding.

Perfect Binding

With perfect binding, the pages are stacked as single sheets, forming the book block, then their back edges are roughened for better adhesion, before being fixed into the spine with a hot-melt or polyurethane reactive (PUR) glue. This is the standard method of binding for paperbacks. The chief benefits of perfect binding are that it is quick and very cost-effective.

Sewn Perfect Binding

With sewn perfect binding, each page section (or “signature”) is first sewn together along its fold edge, then all the signatures are sewn again across the back edge to bind them together into one book block. The whole block is then glued into the spine.

This process is more expensive and time-consuming than perfect binding. The chief benefits are that the book will stay flat when open, will be more durable, and will have an altogether classier look and feel.

Sewn perfect binding is only possible with heavier weights of text paper (at least 100 gsm offset, or 150 gsm silk), and for books of at least 32 pages.

Hardback Binding Explained

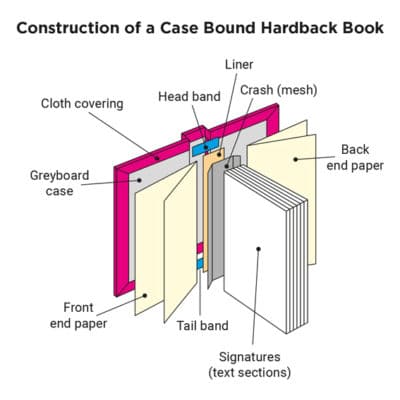

Understanding hardback binding is key to appreciating the various options available. The exploded diagram shows the construction of a typical hardback (case bound) book. In this particular example, the book is cloth-bound (the cloth material is depicted in magenta).

After the required spine width has been calculated, boards are cut for the front cover, back cover and spine. These are then glued in position on the back of the cloth material, leaving a gap between the spine and the cover boards to allow for a flexible folding area, known as a hinge or groove. The cloth is then folded around the edges, trimmed at the corners, and glued onto the inside face of the boards. This assembly forms the cloth-bound cover, known as the case. For a printed paper case (PPC) book, the process is similar, but the printed cover artwork is used in place of the cloth sheet.

Next each page section (or “signature”) is sewn together along its fold edge, then all the signatures are sewn again across the back edge to bind them together into one book block. (Note that perfect binding is also available, though sewn perfect binding is the usual option for hardbacks).

The book block is then glued into the liner and “crash” (a fabric mesh which holds the book block together and fixes it to the covers). At this point, decorative head and tail bands may be added, and possibly even a marker ribbon.

Next, the assembled book block is glued into the case, by means of the crash. Finally, the end papers are glued in. These cover the crash and the edges of the folded-round cloth binding, with which they overlap.

Hardback Options

There are many options for hardback books, but perhaps the most obvious is the choice between a cloth bound hardback with printed dust jacket, or a hardback with printed paper case (PPC), where the printed cover art is glued directly onto the boards.

If you opt for cloth binding with dust jacket, you will be able to choose from a range of standard colours for the cloth material (known as Wibalin), or even go for something a little more bespoke. You may opt to have silver or gold-foiled lettering on the front cover and spine, e.g. showing the title and author. This requires what is known as a block die – you will see this option when ordering.

Cover art will be printed in full colour; this could be in the form of a dust jacket for a cloth-bound book, or the cover wrap for a printed paper case. You can opt to have this laminated, for a smarter finish and protection against damage. You may of course also opt for no jacket if you prefer the simplicity of a traditional cloth-bound finish.

End papers can be printed or plain, with plain papers available in a range of colours, usually chosen to complement your choice of cloth.

For an extra flourish, you could add decorative head and tail-bands, and perhaps even a marker ribbon.

Wire-O Binding Explained

Wire-O binding is typically found in applications such as calendars, company reports, training manuals, diaries and notebooks. One of the great advantages of wire-O bound books is that their pages can be rotated fully 360 degrees – enabling the book to lie flat with a single page to view, which is ideal for notebooks or diaries. The lack of turning resistance at the spine also makes wire-O perfect for calendars. Wire-O can also accommodate different paper thicknesses and sheet widths, making it perfect for applications like business reports or training manuals, where divider tabs may be a requirement.

The binding is achieved by means of a thread of pre-formed wire loops; these are fed through holes punched near the back edge of each page. Once in place, the loops are crimped together to form near-perfect rings, holding the pages in place. We offer a choice of black, silver or white wire as standard. Other colours may be available upon request.